Sound Proof Material Products

GSI can design and install custom quality Noise Control Systems for your:

Generators

Generators- Engines

- Engine Rooms

- Bulkhead Walls

- Hull Walls

- Floors

- Doors

- Ceilings

- Sound Curtains

- Pumps

- Compressors

- Custom Applications

Incredibly versatile when applied to enclosure walls, ceilings, hull walls, carpet underlayment. Multiple thicknesses allow creative solutions for almost any problem area.

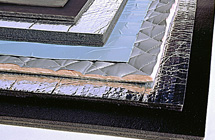

GSI has a wide range of sound proof material products which can be modified to your engineering needs. Foam thicknesses from 1/4″ to 2″, available in a variety of facings, barrier densities and pressure sensitive adhesive backings. Die cut parts can be made to fit your specifications.

GSI provides the additional benefit of thermal insulation margins.

For added safety, all materials are fire retardant.

Noise is quite simply undesirable sound. It is irritating and harmful primarily because of its intensity. At increased intensity sound energy becomes noise and physical as well as psychological harm can occur in humans when exposed to noise for periods of time depending upon the intensity. Physical harm to human beings is easily recognized and measured. Psychological harm although difficult to measure can result in reduced worker efficiency both in quality and quantity of work produced.

How we approach your noise problem

We begin with a basic understanding of the fundamental properties of noise. A noise source produces noise as radiating sound pressure waves, which travel through the air in all directions. We can measure the intensity and calculate the frequency distribution curve. We know that noise radiates from a source and travels along a path to a receiver, the human ear. Using this concept of source-path-receiver we then can formulate various approaches to solving your noise problem.

DESCRIPTION: 1/4″ thick foam Decoupler, 1 lb. per sq. ft. Barrier, ¼” or ¾” foam absorber faced with fiberglass reinforced aluminized mylar. All materials are fire retardant. For use where motor enclosures are thin having relatively little mass.

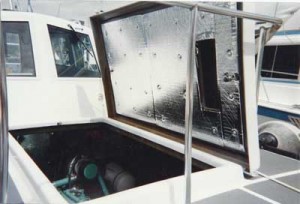

APPLICATION: GSI should be applied on enclosure walls and ceiling and should not touch engine. GSI can be applied to hull walls inside stateroom to absorb noise and provide thermal margin. Use OSI Sound-Stop ½” thick as a carpet underlayment.

ADVANTAGES: GSI will reduce noise levels by minimizing noise reverberation. GSI has a 1 lb. per sq. ft. mass barrier, which yields at least 19 dB STC rating for noise transmission loss. Acoustical foam faced with aluminized mylar means improved aesthetic shiny appearance reverberation elimination and thermal insulation margin.

If you have any questions about our sound proof material products, contact us today.